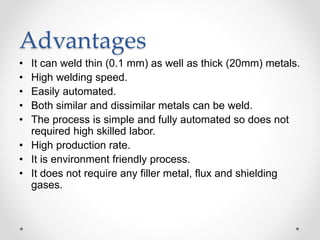

Advantages of Resistance Welding

Carbon dioxide chemical formula CO 2 is a chemical compound made up of molecules that each have one carbon atom covalently double bonded to two oxygen atoms found in the gas state at room temperature. 1 One piece is held stationary while the other piece is rotated.

5 Different Types Of Resistance Welding With Diagram Pdf

What advantages do you get from our Achiever Papers services.

. We are a leading North American provider of the latest in advanced laser welding electron beam welding supply chain management and machine shop services. Ultrasonic welding is the fastest known welding technique with weld times typically between 01 and 10 seconds. In addition to melting the base metal a filler material is typically added to.

2 Two pieces are then brought together as force is applied. Hydraulic machines use liquid fluid power to perform work. In the air carbon dioxide is transparent to visible light but absorbs infrared radiation acting as a greenhouse gasIt is a trace gas in Earths atmosphere at 417.

Definition of Resistance Spot Welding. This heat is further used to melt interface surfaces of welding plates which are held together to form a joint. The method is widely preferred to the conventional soldering process since it prevents frequent heating of the battery.

See Advanced Welding Processes for GMAW on. Buying from the original equipment manufacturer has many advantages. Incorporates many advantages of both spray arc and short circuit transfer and is well.

This method is simple and does not necessary high expert labor. Article about welding soldering and brazing of copper nickel alloys cupronickel. Oxy-Fuel Welding also known as Oxyacetylene Welding but commonly called gas welding this process uses a hand-held torch or blow pipe and a mixture of oxygen and acetylene which combusts to create a flame.

Advantages of Resistance Seam Welding. The spring has high mechanical rigidity to overcome the resistance given by the solids at the bottom of a suspension during mixing. Processes such as gas metal arc welding while often automated are not necessarily equivalent to robot welding since a human operator sometimes prepares the materials to be weldedRobot welding is commonly.

The advantages disadvantages of resistance welding include the following. The fluid is controlled directly or automatically by control valves and. There could be more than one impeller installed in an agitator shaft.

View our current inventory to purchase welders as is or that can be restored to like-new condition. This describes SMAW GTAW and resistance welding similar and dissimilar welding as well as cutting techniques for sheet plate clad plate and piping. In the last session we had discussed the gas welding process and arc welding process and whereas in todays session we will discuss Resistance Spot Welding along with its Definition Construction Working Principle Applications Defects Advantages and Disadvantages.

The use of robotic manufacturing technologies is also growing safer. Robot welding is the use of mechanized programmable tools which completely automate a welding process by both performing the weld and handling the part. Resistance seam welding has the advantage of creating clear welds with no gas formation or welding fume.

The heat required for melting and joining of the plates. This page is for personal non-commercial use. It supplies oxygen at a pressure of about 70 130 Knm2 and gas at 7 103 Knm2 to the welding torch.

Welded components are in use all around us in everyday life such as in aeroplanes bridges buildings cars and ships. Fundamentally STT provides an answer for controlling the welding conditions that can produce incomplete fusion. The rate of production is high.

Welding tips or cutting attachments with the handles can be used for welding heating and cutting operations. The electric current can be supplied to electrodes that also apply. In addition to welding ultrasonic energy is commonly used for processes such as inserting metal parts into plastic or reforming thermoplastic parts to mechanically fasten components made from dissimilar materials.

Yrs 1-2 Native American Studies. Welding is a fabrication process that joins materials usually metals or thermoplastics by using high heat to melt the parts together and allowing them to cool causing fusionWelding is distinct from lower temperature techniques such as brazing and soldering which do not melt the base metal parent metal. 4 Friction creates heat.

Electric resistance welding ERW is a welding process where metal parts in contact are permanently joined by heating them with an electric current melting the metal at the joint. Heavy construction vehicles are a common example. Some dangerous manufacturing tasks such as welding can be carried out by robots.

Today we will learn about gas welding principle working equipments types application advantages and disadvantages. You may order presentation ready copies to distribute to your colleagues customers or clients by visiting https. 3 The force and rotating motion create friction at the faying surfaces which is the interface of the parts being joined.

Resistance Welding Advantages and Disadvantages. Welding has been used to join most metals known to humankind but the process is extensively used for common manufacturing materials such as aluminium steel and titanium. Apart from these laser beam welding explosions and vibrations are some of the other rather extreme processes used for fusing metals.

View this sample Essay any type Diversity and Culture. We are guided by a powerful belief in teamwork and out-of-the-box thinking and we constantly strive to provide our customers with the highest quality and best possible service. Take a look at our latest advancements in laser welding resistance seam spot welding flash welding and post weld heat treating.

Gas welding is a type of liquid state welding process in which fuel gases burns to generate heat. The technique creates a permanent weld and is excellent for the fusion of two materials. Spot welding fuses thin nickel straps to the batterys terminals.

Advantages of Welding Include. Of increasing or decreasing the welding current to increase or decrease heat input. Further it should have a good oxidation resistance and a low thermal conductivity to minimise heat loss and thermal damage.

The design of the tool is a critical factor as a good tool can improve both the quality of the weld and the maximal possible welding speed. Electric resistance welding is widely used for example in manufacture of steel pipe and in assembly of bodies for automobiles. As a result rubbing the two faying surfaces heats the pieces and upsetting the bonding of the parts begins.

It is desirable that the tool material be sufficiently strong tough and hard wearing at the welding temperature. The resistance welding metal thickness is 20mm. A welding connection is more hygienic because it prevents material-build on the fasteners and fittings.

Electrical resistance is used to spot welding straps to nickel-metal hydride lithium-ion batteries or nickel-cadmium cells when manufacturing batteries. In this type of machine hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. Welding offers a variety of advantages including the following.

Native American attempts at assimilation revitalization and resistance. The STT welding mode has the dual benefit of increasing productivity and improving overall weld quality. These impellers are also used to.

The torch assembly consists of the handle Oxygen and fuel gas valves and the mixing chamber. Gas Welding Processes - the most common process being. Robots can detect and avoid humans in the.

Heavy industrials like motorcycles boilers heavy machinery railway locomotives have already started using robots for robotic aluminum welding. There is also no need to use filler materials to make the join which can be made to be both gas and liquid tight offering a.

Resistance Welding Conti Resistance Welding Is A Welding Process In Which Work Pieces Are Welded Due To A Combination Of A Pressure Applied To Them Ppt Download

You Need To Know About Resistance Welding Part 3 It S Type Advantages And Disadvantages Api Cswip Qaqc Level Ii Iii Hvac Fire Fighter Courses By Andt Advanced Institute Of Nondestructive Testing

Resistance Welding Principle Types Application Advantages And Disadvantages Mech4study

0 Response to "Advantages of Resistance Welding"

Post a Comment